News

-

Reactions that occur in stainless steel in high-temperature gases

Hydrogen corrosion may occur in ammonia synthesis, hydrogen desulfurization hydrogenation reactions and petroleum refining units. Carbon steel is not suitable for use in high pressure hydrogen installations above 232°C. Hydrogen can diffuse into the steel and react with ...Read more -

What are the 7 major phenomena of corrosion

Corrosion is a phenomenon in which a material undergoes a chemical or electrochemical reaction with the surrounding material, resulting in disintegration. Whether in our daily life, or in industrial production, metal “rust” can be seen everywhere, from small screw corros...Read more -

Why stainless steel can be magnetic?

Some people think that iron absorption can distinguish between stainless steel and stainless steel. People often magnet adsorption stainless steel belt, verify its merits and authenticity, a suck non-magnetic, that is good, the real thing; sucked magnetic, it is consider...Read more -

Causes and treatment programs on stainless steel welds prone to rusting

In general, the composition of a single pure metal material is not easy to rust. Processed metal in the humid air is prone to rust corrosion phenomenon; and a piece of pure iron even if placed in water will not rust. Stainless steel welding, is spliced on by the welding ...Read more -

Stainless steel products welded after the appearance of several corrosion defects

Stainless steel refers to the amount of chromium is higher than 12% of the steel, chromium in the role of steel is able to form a layer of solid dense Cr2O3 film on the surface of the steel, so that the steel itself and the atmosphere or corrosive media isolation and pro...Read more -

Stainless steel tank pickling passivation and electrolytic polishing effect difference

In recent years, stainless steel tanks are widely used in brewing, pharmaceutical, dairy, chemical, petroleum, building materials, metallurgy and many other industries, and stainless steel tanks in the treatment of surface problems there are two process methods, respecti...Read more -

Factors affecting the passivation film on the surface of stainless steel 304 strap

The passivation film on the surface of 304 stainless steel strap treated with stainless steel passivation solution mainly plays a protective role. However, in actual use, there are many factors that lead to the destruction of the passivation film on the surface of 304 st...Read more -

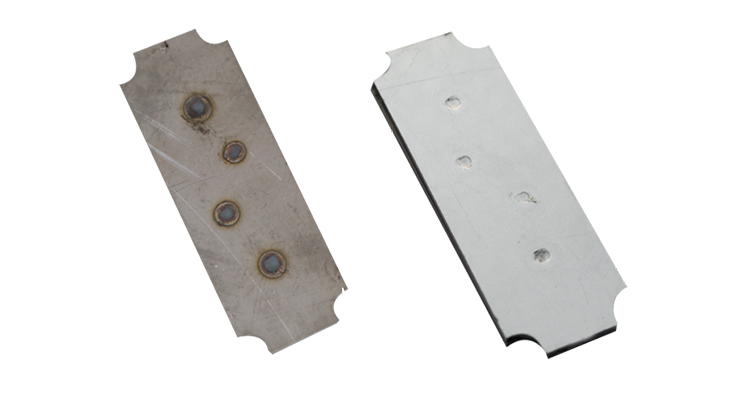

Stainless steel 201 screws for electrolytic polishing salt spray comparison

Stainless steel 201 screws in the process of electrolytic polishing, electrolysis time and salt spray time is a great relationship, then how is the relationship between them? The material we use in this experiment is 201 stainless steel screws, but the workpiece is non-s...Read more -

Advantages of Stainless Steel Pickling and Passivation Solution

In the vast majority of cases, stainless steel products require welding operations. However, after welding, stains such as weld spots and high-temperature oxidized skin will remain on the surface of stainless steel. Weld spots on the welded mouth, the color difference is large, no stainless steel...Read more -

Common Metal Polishing Methods

1. Mechanical Polishing Mechanical polishing is to rely on cutting, plastic deformation of the surface of the material to remove the convex part of the polished surface and get a smooth surface polishing method, generally using oil stone strips, wool wheels, sandpaper, etc., mainly hand-operated,...Read more -

The essential difference between passivation rust prevention and electroplating

Over time, rust spots are inevitable on metal products. Due to variations in metal properties, the occurrence of rust varies. Stainless steel is a corrosion-resistant metal with excellent performance. However, in special environments, there is a need to enhance its corro...Read more -

Common scenarios for the use of stainless steel surface treatment agents

In metal machining processes, the surface of stainless steel products is often contaminated with dirt, and regular cleaning agents may struggle to thoroughly clean it. In general, contaminants on the surface of stainless steel can be industrial oil, polishing wax, high-t...Read more