Industry News

-

Corrosion Causes and Anticorrosion Methods for Aluminum Alloy in High-speed Trains

The body and hook-beam structure of high-speed trains are manufactured using aluminum alloy, known for its advantages such as low density, high strength-to-weight ratio, good corrosion resistance, and excellent low-temperature performance. By replacing traditional steel ...Read more -

Cold rolled steel plate why pickling passivation

Cold rolled steel plate is rolled out on the basis of hot rolled coil, generally speaking, is hot rolled → pickling passivation → cold rolled such a process. Although in the process because of rolling will also make the steel plate temperature, but still called cold roll...Read more -

Introduction to the polishing process of high clean stainless steel pipe

The surface finish of high-clean stainless steel piping system plays a very important role in the safe production of food and drug. Good surface finish has the characteristics of cleanability, reduction of microbial growth, corrosion resistance, removal of metal impuriti...Read more -

Analysis and Solutions to Common Issues in Electrolytic Polishing

1.Why are there spots or small areas on the surface that appear unpolished after electro-polishing? Analysis: Incomplete oil removal before polishing, resulting in residual oil traces on the surface. 2.Why do gray-black patches appear on the surface after polishing? Anal...Read more -

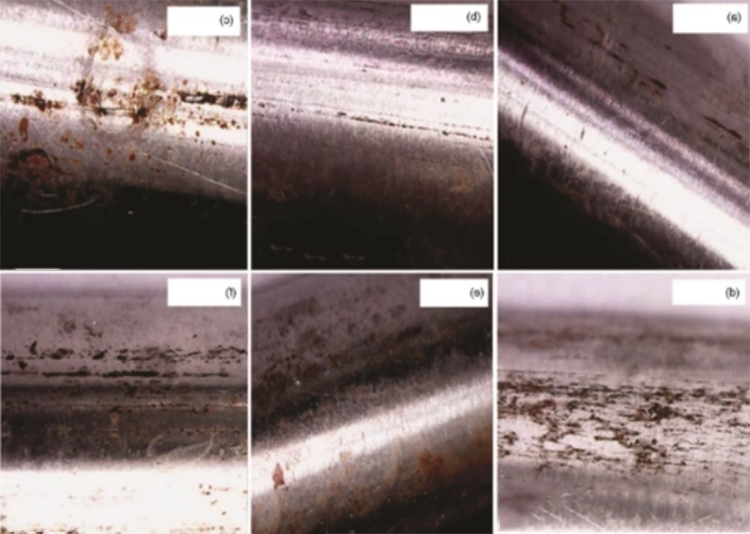

The principle of pitting corrosion of stainless steel and how to prevent pitting corrosion

Pitting corrosion is also called small hole corrosion, pitting or pitting. It is a form of corrosion damage in which most of the surface of the metal does not corrode or corrodes very slightly, but corrosion holes appear in local places and develop deeper. Some pits exi...Read more -

The difference between austenitic and ferritic stainless steel

The main distinction between austenitic stainless steel and ferritic stainless steel lies in their respective structures and properties. Austenitic stainless steel is an organization that remains stable only at temperatures higher than 727°C. It exhibits good plasticity ...Read more -

Polishing Processes for 316 Stainless Steel Hygienic Pipes

The surface cleanliness of stainless steel pipeline systems plays a crucial role in ensuring the safe production of food and pharmaceuticals. A good surface finish helps reduce microbial growth and exhibits corrosion resistance. To enhance the surface quality of 316 stai...Read more -

Can Polishing Treatment Prolong the Service Life of 304 Stainless Steel Pipes?

304 stainless steel pipe polishing treatment is a crucial step in the surface processing of stainless steel pipes, and practically all 304 stainless steel pipes undergo this polishing process. The polishing treatment for stainless steel pipes involves a cutting process ...Read more -

How to deal with rusty stainless steel welds?

First, do electrolytic polishing. Stainless steel weld for electrolytic polishing, can improve the weld surface oxidation resistance, because the smaller the surface roughness of the metal, the better the corrosion resistance. And electrolytic polishing after the stainle...Read more -

Why stainless steel welds are easy to rust?

Stainless steel welds are easy to rust for 3 main reasons First, because the stainless steel weld, is spliced by the welding rod, belongs to the heating processing treatment, resulting in the iron element is not pure, encounter moisture and oxygen in the air, it is easy ...Read more -

Usage Method of Stainless Steel Welded Parts Pickling Passivation Solution

With the continuous development of the metal manufacturing industry, stainless steel materials have found extensive applications in daily life, industrial manufacturing, and military fields. During the processing, fabrication, and use of stainless steel, its surface may ...Read more -

Advantages of Stainless Steel Electrolytic Polishing

1.Formation of Passivation Layer, Improving Corrosion Resistance: The corrosion resistance of stainless steel is based on the formation of a passivation layer consisting of chromium oxide (Cr2O3). Several factors can lead to damage of the passivation layer, including sur...Read more